Sustainability

Imagine a World Illuminated with Organic Lighting…OLED Technology is Good for the Environment AND People

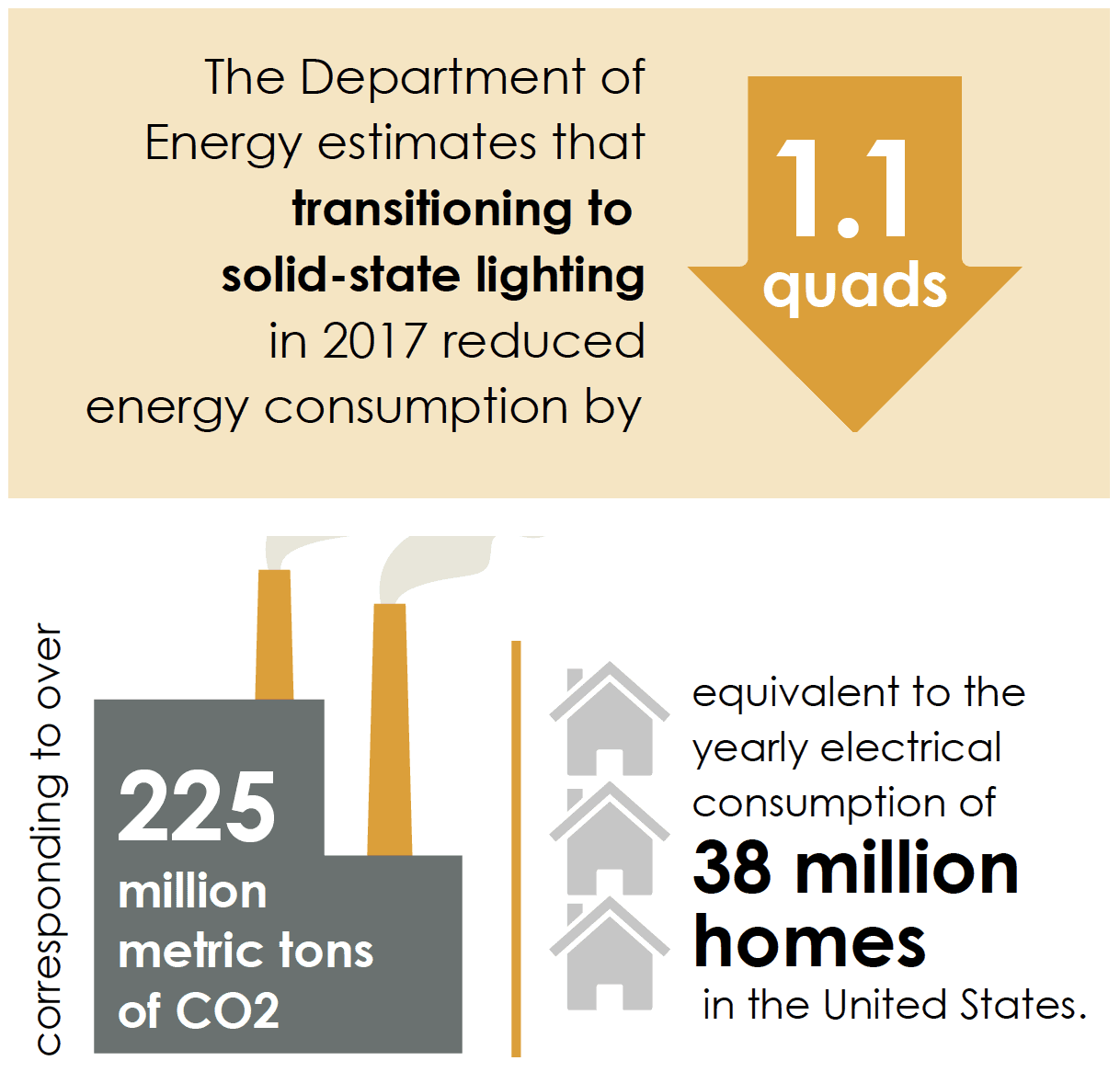

The Department of Energy estimates that transitioning to solid-state lighting reduced energy consumption by 1.1 quads in 2017, corresponding to over 225 million metric tons of CO2e and equivalent to the yearly electrical consumption of 38 million homes in the United States. OLED (organic light emitting diode) technology is one of those types of solid-state lighting. Not only is it ultra-thin, flexible, lightweight, cool to the touch and free of glare, it is extraordinarily sustainable and energy efficient, significantly reducing power and fuel consumption and greenhouse emissions.

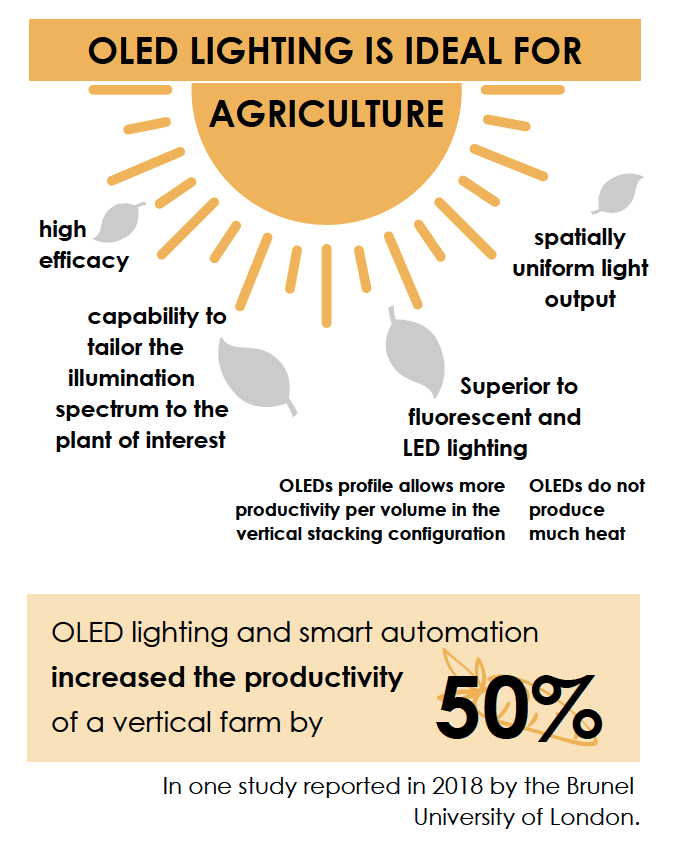

OLEDWorks’ high efficacy solid-state OLED lighting panels reduce energy consumption compared to incandescent lighting, halogen lighting, and even solid-state lighting based on inorganic LEDs. OLED panels are 85% organic material and glass, do not contain toxic metals such as mercury, and have fewer components and a thinner profile compared to lighting based on inorganic LEDs.

Since OLEDs emit from the entire surface of the panel, they do not require the thermal heat sink used in inorganic LED lighting. Life cycle analysis (LCA) studies performed by the Department of Energy have shown that the thermal heat sink often has the highest environmental impact in the manufacturing and disposal steps related to the inorganic LED lighting.

A New York State Energy Research and Development Authority (NYSERDA) project is underway to evaluate the LCA of OLED lighting panels, in collaboration with Rochester Institute of Technology.

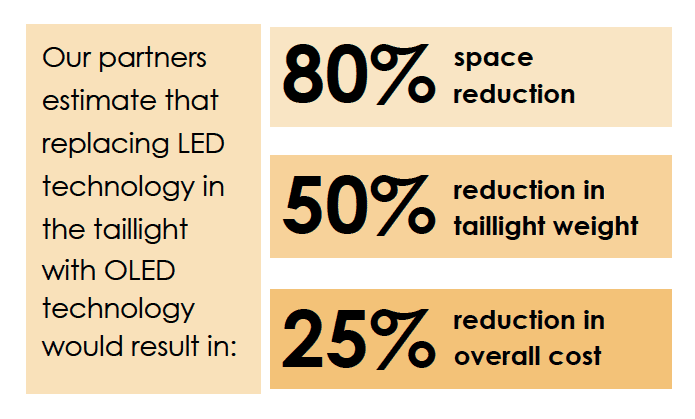

OLED in Automotive

Design Benefits

- Reduced lighting system weight in vehicles allows improved fuel efficiencies and reduced emissions

- Fewer lighting fixture components and use of non-toxic materials results in compact profiles, a reduced manufacturing footprint, and easier recycling at end-of-life

- Glare-free and cooler operating temperatures allow placement of lighting fixtures closer to the end-user, reducing the number of fixtures required, overall power requirements and greenhouse gas emissions.